| Cylinder Overhaul Process

At Vintage Radials we have maintained excellent overhaul standards to return any model of cylinders back in service.

Experienced technicians in our Cylinder Overhaul Department have the knowledge and capability to overhaul any Pratt & Whitney or Curtiss Wright model radial engine cylinder.

Here is a list of models we overhaul cylinders for:

Curtiss-Wright - R975, R1300, R1820, R2600, R3350

Pratt & Whitney - R985, R1340, R1830, R2000, R2800, R4360

We maintain an extensive library of current data for overhauling any model of cylinders.

Our standard overhaul procedures are performed in accordance with the current manufacturer specifications manuals.

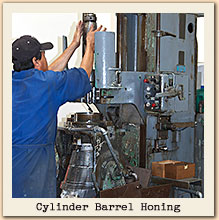

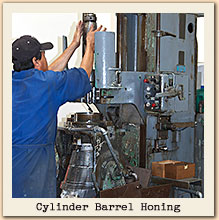

1. Cylinder barrels are honed and inspected visually and dimensionally to determine their suitability for service.

2. Cylinder parts are thoroughly cleaned for inspection.

3. Cylinders components are inspected using dye penetrant or Zyglo methods to provide accurate and reliable detection of cracks and other surface discontinuities to verify the integrity of cylinder components.

4. All overhauled cylinders have new valve guides and seats installed.

5. Cylinder valve and rocker assemblies are set to manufacturer's service limits.

6. Cylinder piston heads are re-grooved to recondition ring lands.

7. Cylinders components are reassembled per manufactures instructions.

8. Overhauled cylinders are packed and shipped to customer or installed in the engine if part of an complete engine overhaul project. |

<>

|